shirubaby

Senior Member

Ever wanted to control your stereo from buttons mounted on the steering wheel? Well here's how...

But first a disclaimer.

WARNING: to follow this advice is to muck around with the steering wheel...and thus with airbags. My advice is dont do it unless you are comfortable with working around airbags.

My steering wheel did not come with an airbag so this was not a problem. Also one of the units I have developed is embedded in the steering wheel.

But if you want to read on then this is what I did (with pics numbered 1 to ?? from left to right).

Objective and preamble:

To mount micro switches around the steering wheel that when pressed will control a JVC stereo.

Functions i wanted on the multi-function steering wheel where:

Volumn up/down,

Search forward/backwards for radio,

Skip track forward/backwards for ipod,

Cycle through equalizer presets

Select music source

Ipod menu up/down

The stereo I have installed in my car is a jvc kd-g421. I guess it will work with most jvc car stereos. The jvc stereo is coupled with an ipod integration kit (£39.99 special offer from Halfords) which means I can remotely control my ipod as well...cool. This kit (ks-pd100) charges the ipod and transfers music through the dock port on the ipod. It also allows control of ipod through the stereo buttons.

The unit also contains, at the back, a 3.5mm stereo jack input to be hooked up to factory fitted multifunction steering wheels and stalks on many cars...and interface devices already exist (made by Autoleads etc.). But what if you dont have factory fitted steering wheel buttons and remote stalks?

My 1989 300ce was one of those cars that had nothing on the steering wheel...or anywhere near.

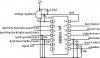

I knew the JVC stereo took in a set of bit pusles as a pattern (thorugh the 3.5mm stereo jack); and depending on the code transmitted did various things (like vol up/down etc.). To generate a bit pattern i needed a microcontroller and some assembly code.

You can read the original forum thread I participated in to get a better idea of what kind of pulses the jvc needed:

http://www.avforums.com/forums/showthread.php?t=248455&highlight=diy+jvc+remote

Now at the start of my research I could have taken one of 2 directions. I could create a button pod that i could mount on the fixed steering column. This is easier and would require only one microcontroller circuit. However the 300ce steering wheel is quite large and it is difficult to reach round to any column-mounted pod.

The other research direction (potentially more difficult) was to mount the control buttons round the moving steering wheel. Whilst being easier to reach I was faced with the problem that the wheel will move round and any wires passed though the steering wheel will get snagged round the steering shaft. So how do factory fitted steering wheel buttons work? ONe answer, as with the case of BMW, is to spring load the wires so that they stretch when the wheel is turned and retract, to the correct length, when the wheel is returned to the original position. Geez...complicated.

The other answer is metal concentric slip rings which are present in all steering wheels. There are 2 in every steering wheel and are used for the horn. Suffice to say that slip rings and their associated contacts on the other side (of the steering-wheel/steering-column boundry) allow any electrical circuit to stay connected even when the wheel is moving. For each of the buttons on a multi-function steering wheel there will be a slip ring and associated pin-contact.

BUT my merc only had 2 slip rings and they where being used for the horn. How could I add more slip rings? Then my friend John came up with a great idea.

Why not remove the horn, create a microcontroller cicuit (housed within the moving steering wheel) that utilised the slip ring electrical circuit configuration to send bit pulses to the stereo.

But what about the horn...you might ask?

To solve this we use an extra microcontroller circuit, in-line between the 1st microcontroller circuit and the stereo, which will do 2 things:

1. relay the bit pulses (as is) to the stereo

2. recognise a bit pulse unique to the horn function and then energize a relay to sound the horn for a specific period of time - the unique horn pulse will be generated by the 1st microcontroller circuit when the horn is pressed.

Electronic circuit diagram is to follow...

All of this sounds complicated but the diagrams and pictures will help.

What you need:

Basic Knowledge of simple electronics

Simple soldering skills

A pic programmer (ebay buy)

2 pic micontrollers (free samples can be ordered from microchip.com) - a 16F688 for the circuit inside the steering wheel and a 12F629 for the in-line circuit

1x 12v relay

Some resistors (see circuit diagram)

1x NPN transistor

2x 5v voltage regulators

2x cases to house the circuits

2 pieces of veroboard (one for each circuit)

speaker wire for moving bit patterns from the steering wheel to the stereo

3.5mm stereo jack

7 amp wire to interface the relay to the horn wires.

some small core wire to move 5v levels around the circuit board (if necessary)

most of the above can be ordered from rapid electronics, farnell.co.uk or maplins. And should not cost you more than £25

Phew...I'm tired of writing. Will complete the rest. Now I'm off to gather my notes and draw a circuit diagram.

But first a disclaimer.

WARNING: to follow this advice is to muck around with the steering wheel...and thus with airbags. My advice is dont do it unless you are comfortable with working around airbags.

My steering wheel did not come with an airbag so this was not a problem. Also one of the units I have developed is embedded in the steering wheel.

But if you want to read on then this is what I did (with pics numbered 1 to ?? from left to right).

Objective and preamble:

To mount micro switches around the steering wheel that when pressed will control a JVC stereo.

Functions i wanted on the multi-function steering wheel where:

Volumn up/down,

Search forward/backwards for radio,

Skip track forward/backwards for ipod,

Cycle through equalizer presets

Select music source

Ipod menu up/down

The stereo I have installed in my car is a jvc kd-g421. I guess it will work with most jvc car stereos. The jvc stereo is coupled with an ipod integration kit (£39.99 special offer from Halfords) which means I can remotely control my ipod as well...cool. This kit (ks-pd100) charges the ipod and transfers music through the dock port on the ipod. It also allows control of ipod through the stereo buttons.

The unit also contains, at the back, a 3.5mm stereo jack input to be hooked up to factory fitted multifunction steering wheels and stalks on many cars...and interface devices already exist (made by Autoleads etc.). But what if you dont have factory fitted steering wheel buttons and remote stalks?

My 1989 300ce was one of those cars that had nothing on the steering wheel...or anywhere near.

I knew the JVC stereo took in a set of bit pusles as a pattern (thorugh the 3.5mm stereo jack); and depending on the code transmitted did various things (like vol up/down etc.). To generate a bit pattern i needed a microcontroller and some assembly code.

You can read the original forum thread I participated in to get a better idea of what kind of pulses the jvc needed:

http://www.avforums.com/forums/showthread.php?t=248455&highlight=diy+jvc+remote

Now at the start of my research I could have taken one of 2 directions. I could create a button pod that i could mount on the fixed steering column. This is easier and would require only one microcontroller circuit. However the 300ce steering wheel is quite large and it is difficult to reach round to any column-mounted pod.

The other research direction (potentially more difficult) was to mount the control buttons round the moving steering wheel. Whilst being easier to reach I was faced with the problem that the wheel will move round and any wires passed though the steering wheel will get snagged round the steering shaft. So how do factory fitted steering wheel buttons work? ONe answer, as with the case of BMW, is to spring load the wires so that they stretch when the wheel is turned and retract, to the correct length, when the wheel is returned to the original position. Geez...complicated.

The other answer is metal concentric slip rings which are present in all steering wheels. There are 2 in every steering wheel and are used for the horn. Suffice to say that slip rings and their associated contacts on the other side (of the steering-wheel/steering-column boundry) allow any electrical circuit to stay connected even when the wheel is moving. For each of the buttons on a multi-function steering wheel there will be a slip ring and associated pin-contact.

BUT my merc only had 2 slip rings and they where being used for the horn. How could I add more slip rings? Then my friend John came up with a great idea.

Why not remove the horn, create a microcontroller cicuit (housed within the moving steering wheel) that utilised the slip ring electrical circuit configuration to send bit pulses to the stereo.

But what about the horn...you might ask?

To solve this we use an extra microcontroller circuit, in-line between the 1st microcontroller circuit and the stereo, which will do 2 things:

1. relay the bit pulses (as is) to the stereo

2. recognise a bit pulse unique to the horn function and then energize a relay to sound the horn for a specific period of time - the unique horn pulse will be generated by the 1st microcontroller circuit when the horn is pressed.

Electronic circuit diagram is to follow...

All of this sounds complicated but the diagrams and pictures will help.

What you need:

Basic Knowledge of simple electronics

Simple soldering skills

A pic programmer (ebay buy)

2 pic micontrollers (free samples can be ordered from microchip.com) - a 16F688 for the circuit inside the steering wheel and a 12F629 for the in-line circuit

1x 12v relay

Some resistors (see circuit diagram)

1x NPN transistor

2x 5v voltage regulators

2x cases to house the circuits

2 pieces of veroboard (one for each circuit)

speaker wire for moving bit patterns from the steering wheel to the stereo

3.5mm stereo jack

7 amp wire to interface the relay to the horn wires.

some small core wire to move 5v levels around the circuit board (if necessary)

most of the above can be ordered from rapid electronics, farnell.co.uk or maplins. And should not cost you more than £25

Phew...I'm tired of writing. Will complete the rest. Now I'm off to gather my notes and draw a circuit diagram.