47p2

Senior Member

- Joined

- May 3, 2006

- Messages

- 3,583

- Reaction score

- 5

- Location

- Scotland

- Your Mercedes

- W638, W140, W220, W639 All gone but not forgotten

DIY Garage Building (Picture Heavy)

From start to finish this project was a huge learning curve for me as I had never tackled anything on this scale before, so I thought I would share my story with you and show what a mammoth task I started and eventually finished some 21 months later.

This is the plot of land where the garage will be sited. I have already cut down the trees, all 10 of them. They were over 85 feet tall and it was not a pleasant or easy job cutting them down.

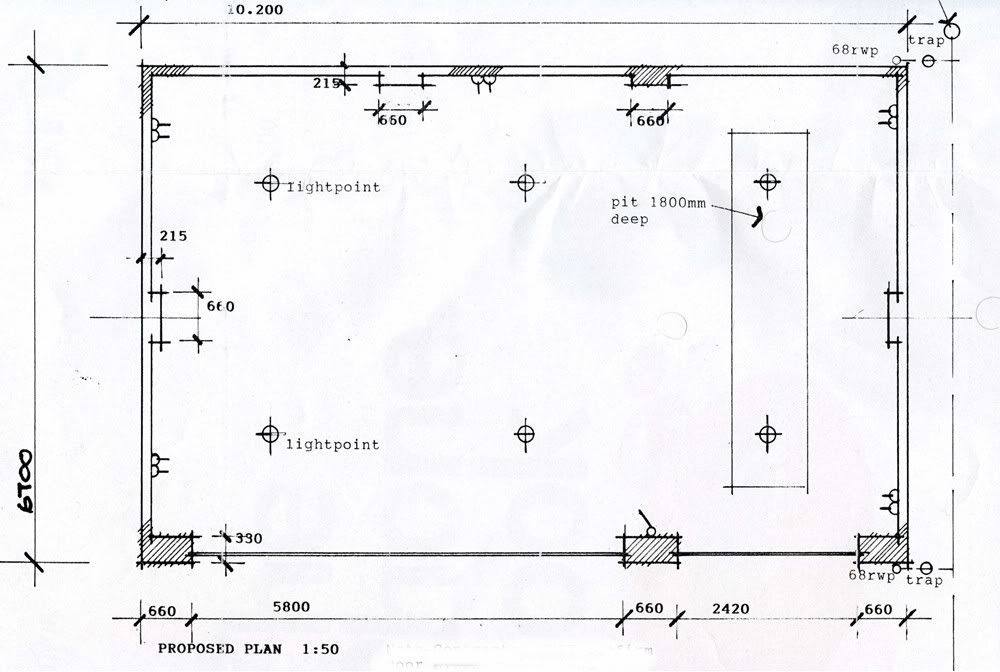

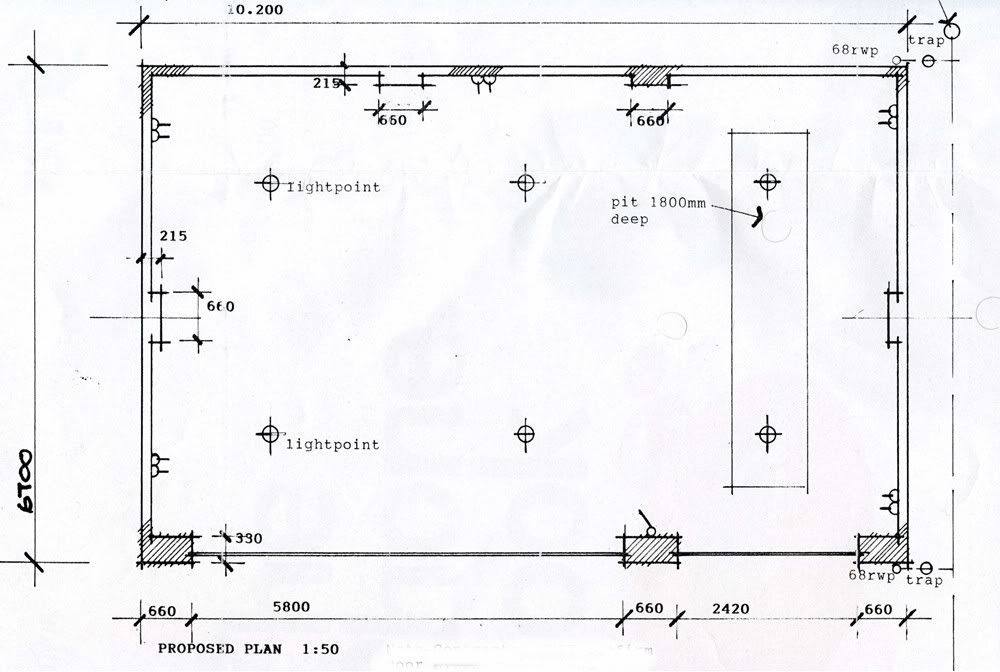

This is the Plan of the garage floor. It will be almost 33.5 feet by 22 feet and will have a pit at one side

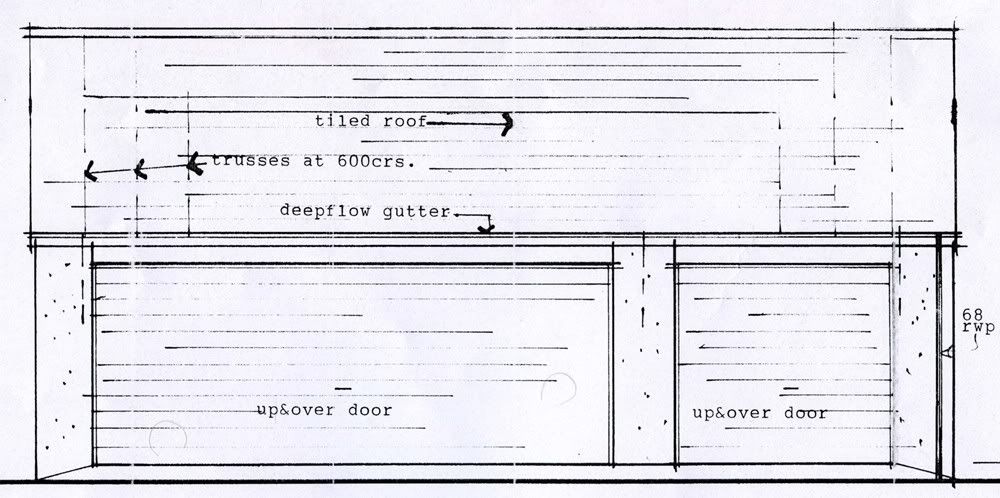

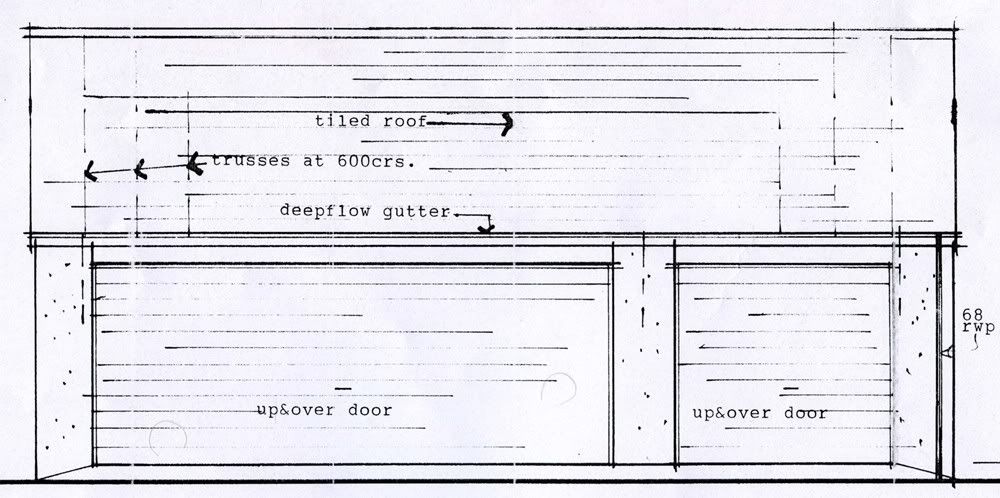

This is the Front Elevation. A double door to the left and a single to the right. The door clearance height is 7.8 feet

.

.

Let the work commence......

What a day....All the treee stumps have been removed and digging of the foundations has started. This was not without problems as one of the tracks came off the excavator and I had to call the company to find out how to release the tension to refit the track.....

All very easy if you are Charles Atlas, but we did get it back on after a bit of huffing and puffing.....

These pictures do not show the true size of the stumps as the largest is oner 4 foot tall

.

.

From start to finish this project was a huge learning curve for me as I had never tackled anything on this scale before, so I thought I would share my story with you and show what a mammoth task I started and eventually finished some 21 months later.

This is the plot of land where the garage will be sited. I have already cut down the trees, all 10 of them. They were over 85 feet tall and it was not a pleasant or easy job cutting them down.

This is the Plan of the garage floor. It will be almost 33.5 feet by 22 feet and will have a pit at one side

This is the Front Elevation. A double door to the left and a single to the right. The door clearance height is 7.8 feet

Let the work commence......

What a day....All the treee stumps have been removed and digging of the foundations has started. This was not without problems as one of the tracks came off the excavator and I had to call the company to find out how to release the tension to refit the track.....

All very easy if you are Charles Atlas, but we did get it back on after a bit of huffing and puffing.....

These pictures do not show the true size of the stumps as the largest is oner 4 foot tall

Last edited: