OK so I've bit the bullet following a blown head gasket and decided this is as good a time as any to strip the engine and give it an overhaul.

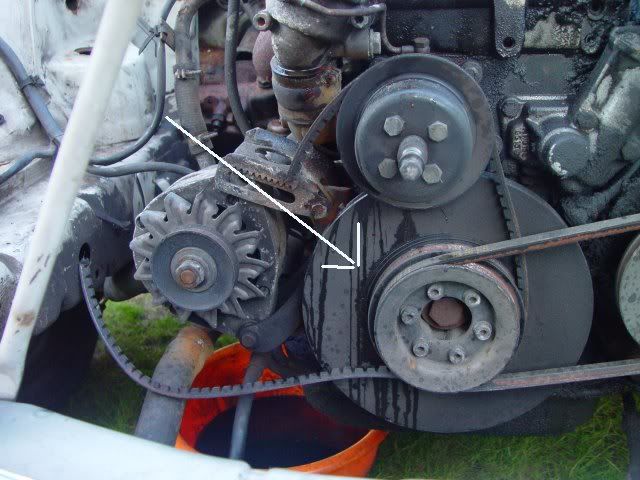

Brave as never done anything like this before. First problem - how do I remove the crankshaft pulley so I can remove the front of the block and reveal the timaing chain etc.

I don't want to go at this without insight so any help gratefully received.

Brave as never done anything like this before. First problem - how do I remove the crankshaft pulley so I can remove the front of the block and reveal the timaing chain etc.

I don't want to go at this without insight so any help gratefully received.