- Joined

- Mar 25, 2010

- Messages

- 15,138

- Reaction score

- 6,296

- Location

- Tonbridge

- Your Mercedes

- W221 S65 AMG - W204 C63 AMG + Various other MB's

- Moderator

- #1

My 123 240D has 230,000 on the clock, and I am willing to bet its genuine!At traffic lights etc, it has been blowing out white smoke, which is normally an indication of poor injector spray pattern. It also gives intermittent diesel knock at part loads and idle. Time to replace the nozzles in the injectors and give them a clean and calibration!You will need:

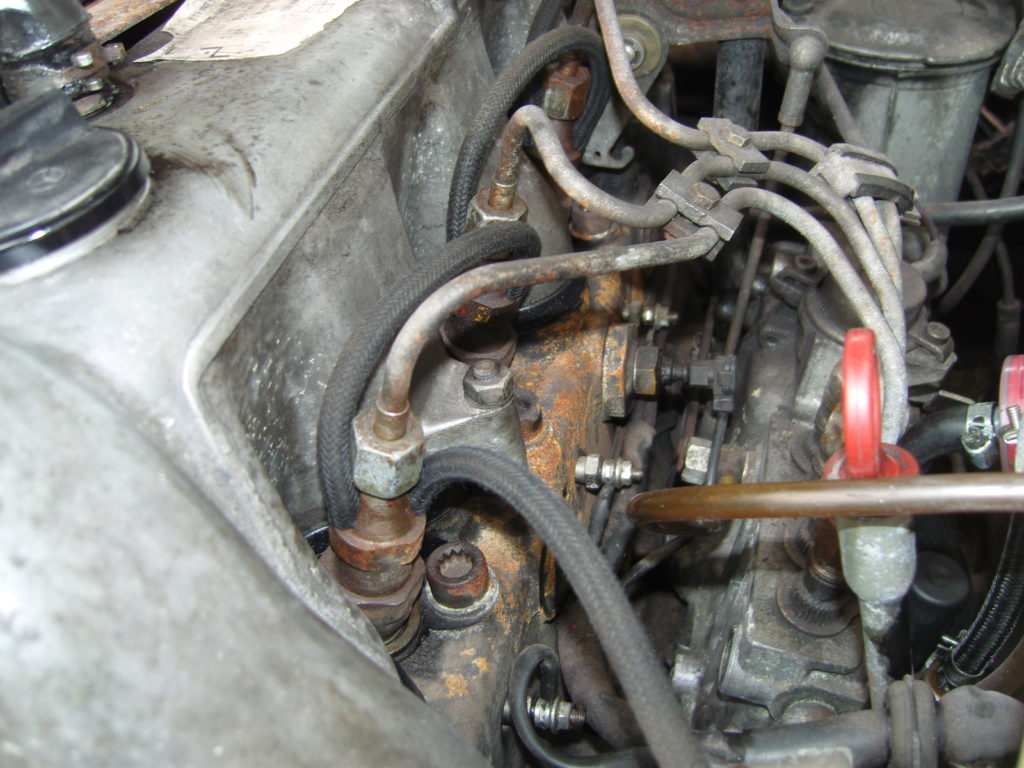

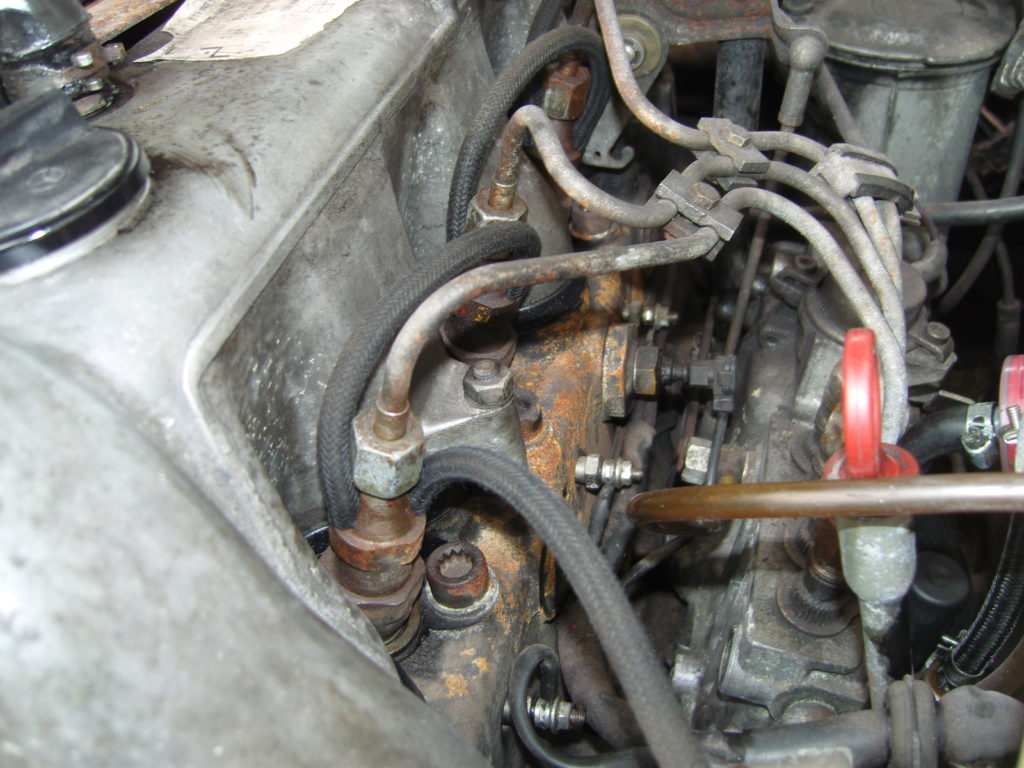

Ensure you cover any open injection lines to prevent dirt getting into the lines/pump.

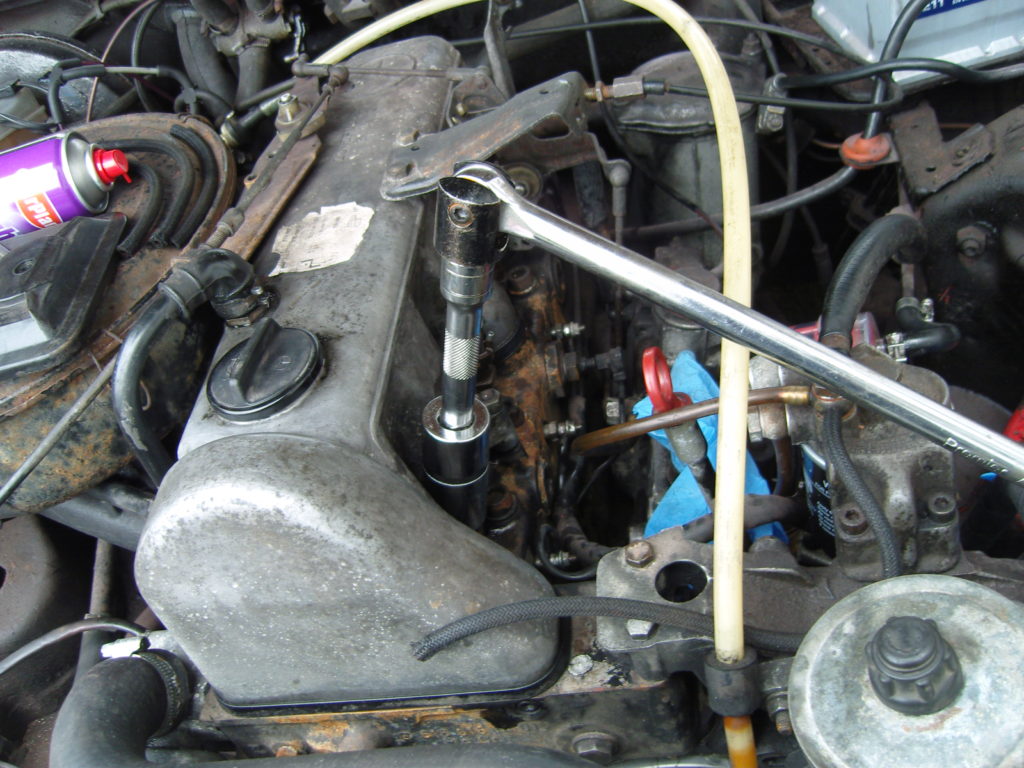

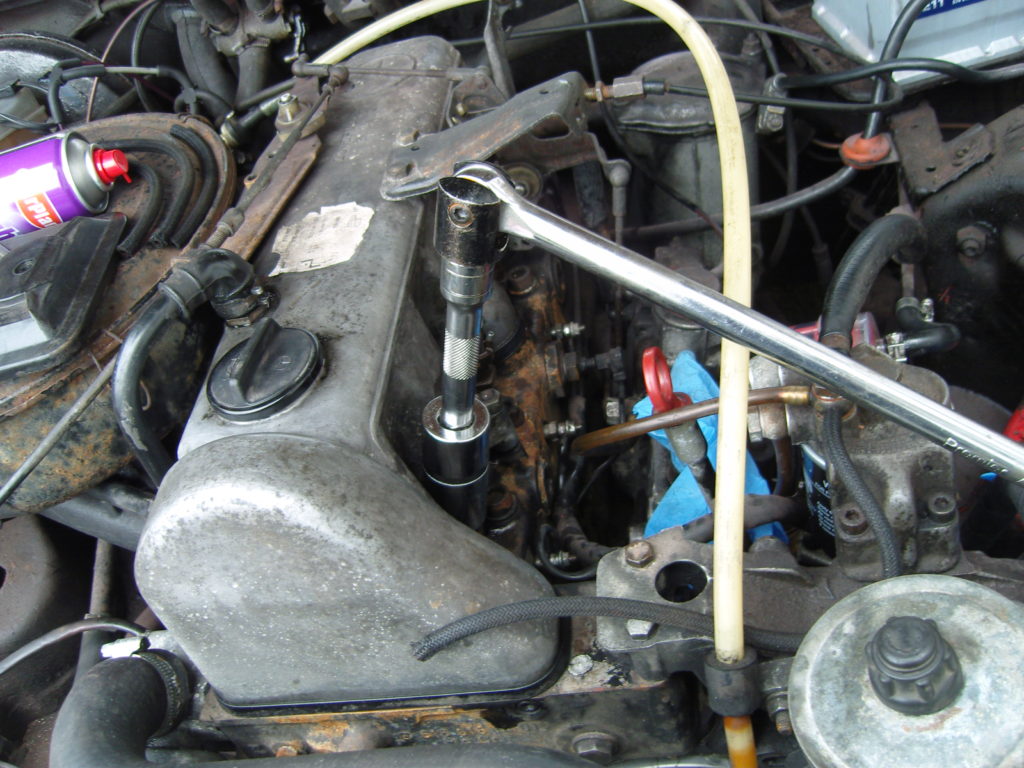

Remove the injectors with a 27mm deep socket.

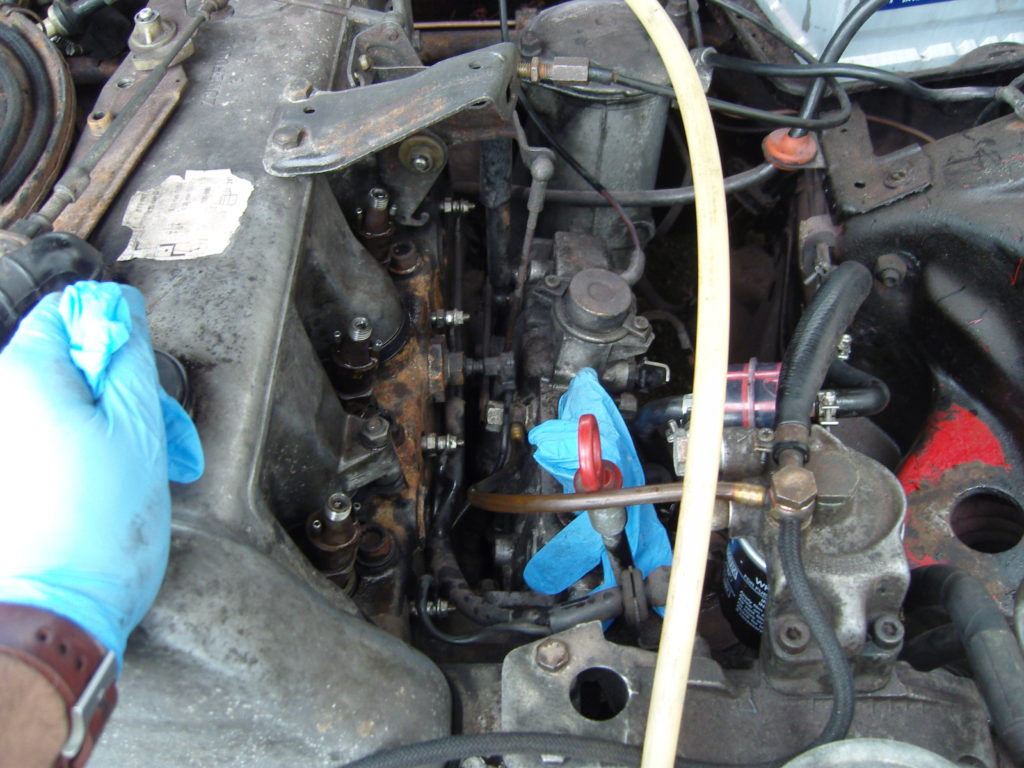

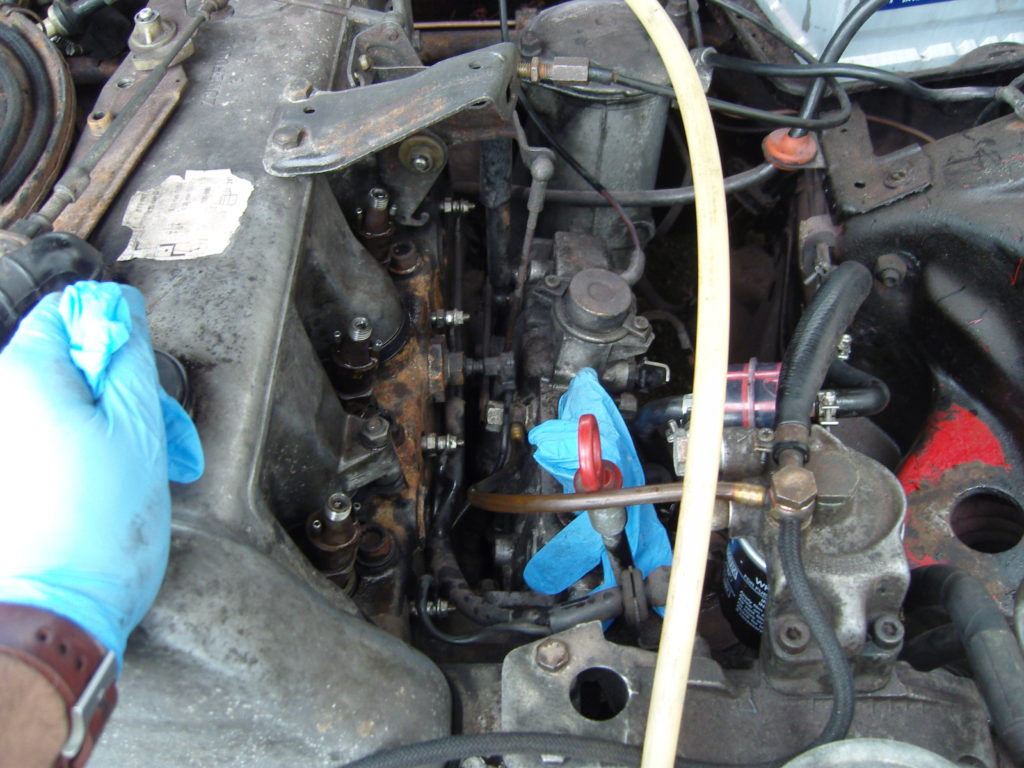

Ensure you fill the holes with something to stop debris getting into the engine.

Bring the injectors inside and bolt them into a vice upside down.

Use the same 27mm socket to split the injector half's. If they are quite old, you may have to apply some considerable force to split them. Once you have them apart, you will find these bits inside:

The object in the middle is the nozzle holder and nozzle. Chuck that away, as we will be replacing them.Put the rest of the objects into an ultrasonic cleaner with some hot water and degreaser:

I also went over the injector body's with a wire brush:

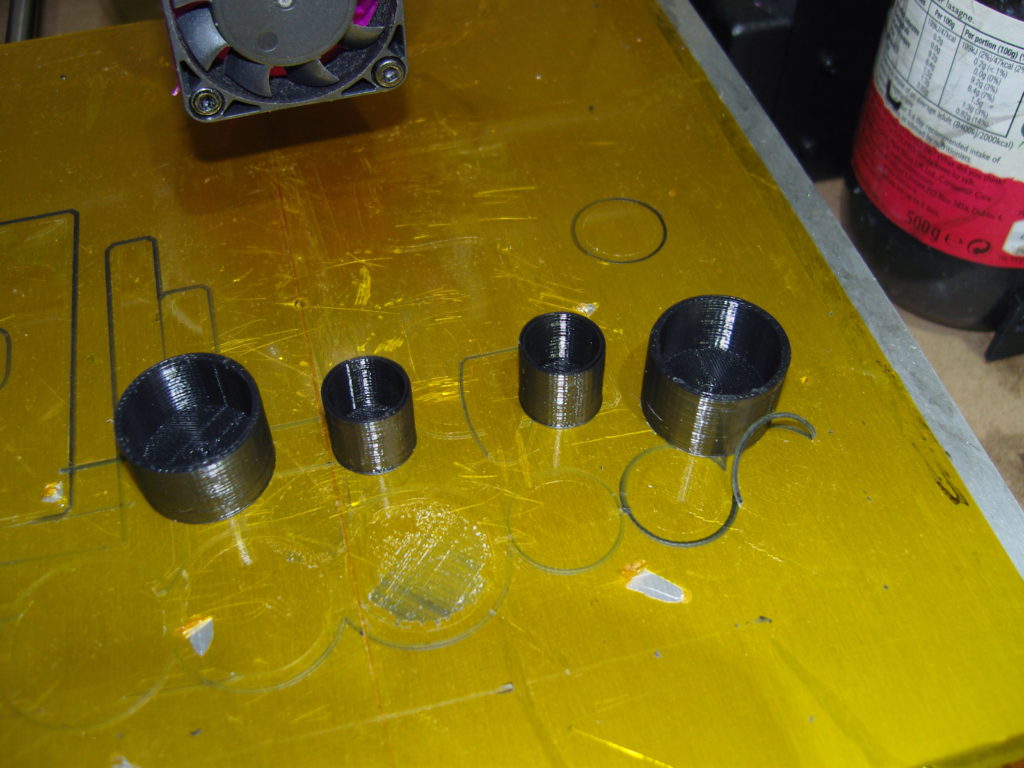

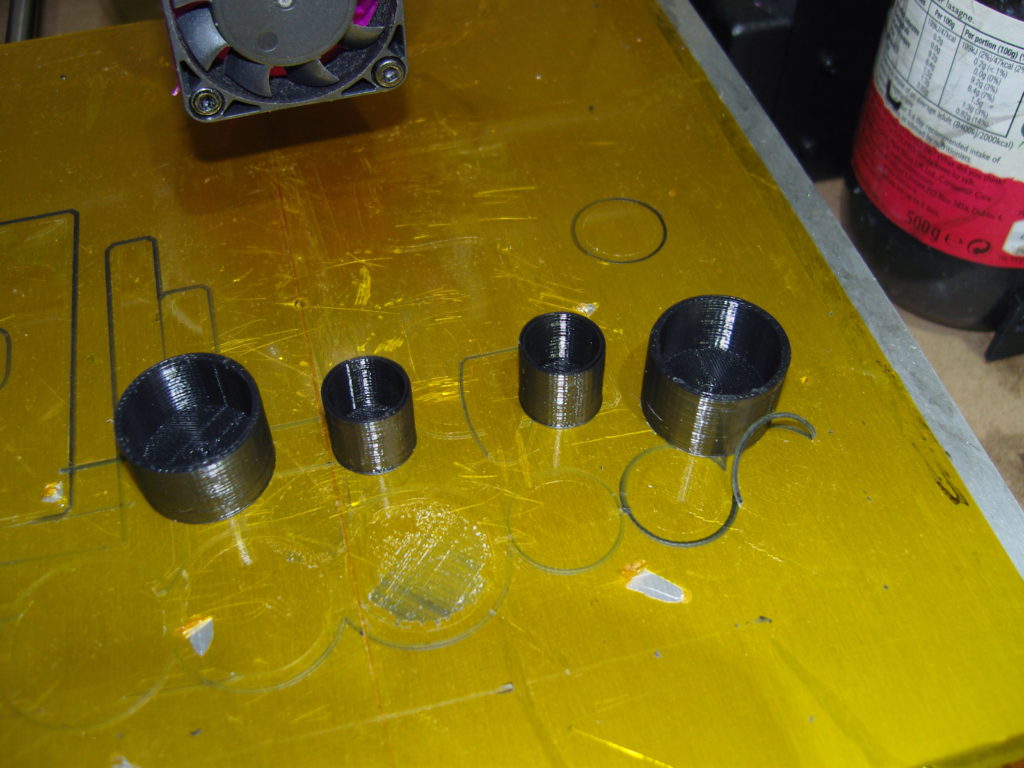

Bonus, injector tip and feed line caps, 3d printed whilst I was cleaning them:

Once they are clean, clamp the injector top into the vice upside down, and replace the internals, making sure you put the hat the right way round. Balance the new nozzle on top and screw down. Torque the injector half's tightly but don't torque them up fully, as we still need to adjust the pop pressure. It may be advisable to lap the seating cone and the injector half's if they show signs of corrosion or damage to the seat. If your injectors leak at the join between the top an the bottom, you should lap them in.Once re-assembled, bolt them into the pop tester, and see what pressure they pop at. We are aiming for 115BAR on these.

You also want to pump them up close to pop pressure, and ensure they a) hold pressure and b) don't dribble. There should be a clear pressure that they pop at.

Repeat the process for all 4 injectors, make sure you get them with 3 bar of each other.Re-install with the new heatshield washers. When you re-install, leave the injector lines loose at the injectors, and crank the engine until fuel comes out, then tighten them and the engine should start without issues.

A link to the article:

http://fotifixes.com/2016/04/23/w123-injector-rebuild-and-calibration/

- 27mm deep socket.

- Vice

- Ultrasonic cleaner (preferably)

- 4 x Replacement injector nozzles (I used Monarch*DN0SD261, newer Bosch nozzles are of questionable quality)

- 4 x Injector heat shield*washers.

- Injector pop tester

- Injector adustment shims

- Remove the injector lines:

Ensure you cover any open injection lines to prevent dirt getting into the lines/pump.

Remove the injectors with a 27mm deep socket.

Ensure you fill the holes with something to stop debris getting into the engine.

Bring the injectors inside and bolt them into a vice upside down.

Use the same 27mm socket to split the injector half's. If they are quite old, you may have to apply some considerable force to split them. Once you have them apart, you will find these bits inside:

The object in the middle is the nozzle holder and nozzle. Chuck that away, as we will be replacing them.Put the rest of the objects into an ultrasonic cleaner with some hot water and degreaser:

I also went over the injector body's with a wire brush:

Bonus, injector tip and feed line caps, 3d printed whilst I was cleaning them:

Once they are clean, clamp the injector top into the vice upside down, and replace the internals, making sure you put the hat the right way round. Balance the new nozzle on top and screw down. Torque the injector half's tightly but don't torque them up fully, as we still need to adjust the pop pressure. It may be advisable to lap the seating cone and the injector half's if they show signs of corrosion or damage to the seat. If your injectors leak at the join between the top an the bottom, you should lap them in.Once re-assembled, bolt them into the pop tester, and see what pressure they pop at. We are aiming for 115BAR on these.

You also want to pump them up close to pop pressure, and ensure they a) hold pressure and b) don't dribble. There should be a clear pressure that they pop at.

Repeat the process for all 4 injectors, make sure you get them with 3 bar of each other.Re-install with the new heatshield washers. When you re-install, leave the injector lines loose at the injectors, and crank the engine until fuel comes out, then tighten them and the engine should start without issues.

A link to the article:

http://fotifixes.com/2016/04/23/w123-injector-rebuild-and-calibration/

Last edited: