OP

EdPhil

Active Member

- Joined

- May 2, 2023

- Messages

- 34

- Reaction score

- 35

- Your Mercedes

- cls shooting brake 2014 350 E class estate 2011 250

- Thread Starter

- Thread starter

- #41

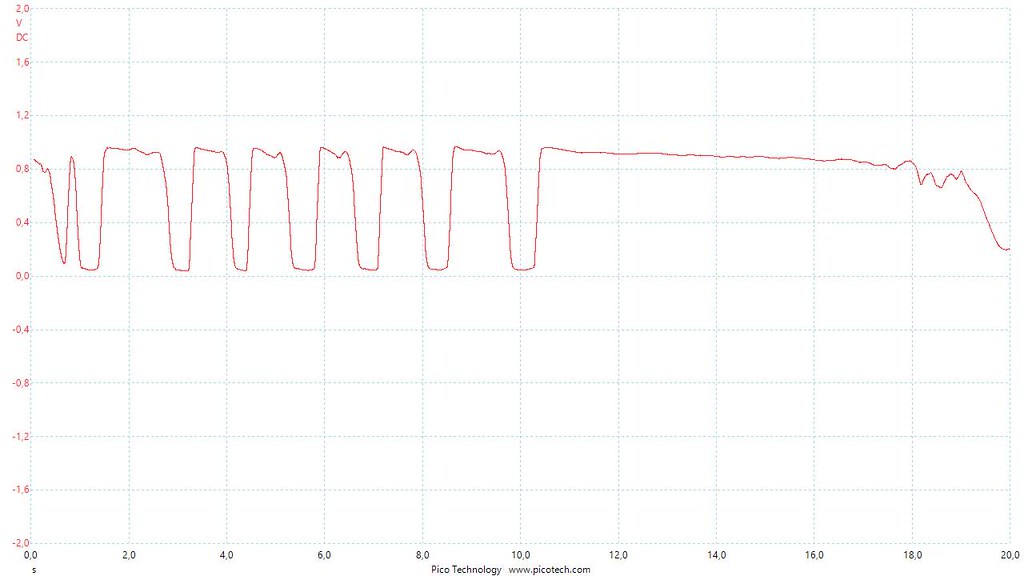

I think I should say that I have not gone a bit quiet because I have decided to drop this. As I have not managed to get any NOx graphing details etc. yet from anybody who has installed upgraded NOx sensors (I am of the opinion that garages just fit and hope without operational testing and graphing), and Xentry is (in my opinion) not designed to provide very detailed diagnostics of components, I am diving a lot deeper into the individual ECU units' software with more sophisticated diagnosis tools. This takes a lot of time but is also very enlightening - still working on it.

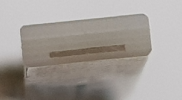

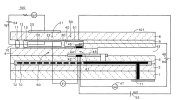

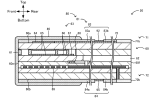

Another thing I have been doing is checking the NGK and Continental patents, which should be detailed enough to know exactly how the Control Unit and Sensor work together - again, still working on it. However, I have a pretty good understanding now of how the sensor ceramic chip (the bit at the heart of the sensor) is manufactured and works, and what those eight wires are for - that's a question lots ask on the internet, but I have not seen anybody answer properly yet!!

I have been servicing the CLS this week, so its been in my garage and not done any mileage.

Best Regards:

Edward

Another thing I have been doing is checking the NGK and Continental patents, which should be detailed enough to know exactly how the Control Unit and Sensor work together - again, still working on it. However, I have a pretty good understanding now of how the sensor ceramic chip (the bit at the heart of the sensor) is manufactured and works, and what those eight wires are for - that's a question lots ask on the internet, but I have not seen anybody answer properly yet!!

I have been servicing the CLS this week, so its been in my garage and not done any mileage.

Best Regards:

Edward