Blobcat

Moderator

- Joined

- Feb 8, 2006

- Messages

- 39,026

- Reaction score

- 27,852

- Location

- Grange Moor

- Your Mercedes

- R171 SLK280, Smart R451, Land Rover 110 County SW, 997 C2S, R1250 GSA TE 40th, CBR600FP

- Moderator

- #21

Evening all.. did a few more bits on Wednesday mainly on the rear end.

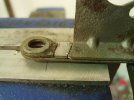

While I gather enough steam to make that upload, please see the repair of my friends blasting pot (that I broke) in preparation for blasting a few bits on the car which I want cleaned but hard to get at with my usual bits.

Gravity blasting pot - broken leg repair.

Evening all, I borrowed a blasting part of a friend a good while back nearly two years ago i'd say. The design was crap, which meant when I filled it with shot the front leg broke off, quite annoying. Anyway, I had been planning on repairing it but never got around to it until yesterday. I need...www.mig-welding.co.uk